About

Established in 1966

CFW Fans has built a reputation for quality products and superb service over more than fifty years, reflecting our commitment to delivering durable products with high engineering standards. The expertise built up over this time has given us technical design and manufacturing skills to offer effective products with greater long-term benefits than cheaper alternatives.

CFW’s solid approach to business and commitment to partnering with our clients makes us the right choice for any company that requires an air technology solution that will last.

- Quality Products: We provide durable, high-quality fans that will deliver the best overall value, which includes robustness, reliability, efficiency, and back-up service.

- Well-established: CFW has been in business since 1966 and has grown from strength to strength in infrastructure, manufacturing methods, intellectual property, and a deep understanding of industrial fans and fan related systems.

- Excellent Service: From original enquiry through purchase order to after-sales service we remain committed to customer satisfaction.

- Bespoke Solutions: Fans can be custom-made or modified according to customer specifications.

- Professional Engineering: Our advanced manufacturing facilities and extensive fan engineering expertise mean that we can provide superior product selection, product development, manufacture and installation.

Quality

CFW is an SABS ISO 9001 quality management system certified company. The innovation and production of quality products that can withstand the rigours of modern industrial duty has been an essential building block in the success of CFW Fans.

Customer Service

A solutions-driven sales approach, combined with dedication to after-sales service, has gained CFW Fans the reputation of being a company that stands by its products. From original enquiry through purchase order to after-sales service, we remain committed to customer satisfaction.

A consulting service is offered to those customers requiring design assistance. Products are distributed to our markets either directly from our Cape Town or Johannesburg depots or via well-established agencies in key areas.

Manufacturing

Our manufacturing facility is constantly upgraded to incorporate the latest manufacturing methods and CNC machinery (CAD/CAM equipment), thus ensuring competitiveness, consistency and quality.

Facilities include:

- CNC Forming

- Aluminium Foundry

- CNC Punching & Bending

- CNC Laser Cutting System

- Dynamic Balancing in factory and on site

- CNC Lathes & Machining Centre

- Fan Testing Facility to ISO 5801 Test Standard

- Flame Cutting & Welding (MMA, MIG/MAG & TIG)

- Mild & Stainless Steel Plate & Sheet Metal Fabrication

Product Design and Development

A wide range of documented, pre-engineered fans is available which have been designed and tested to ISO 5801 and BS 848 Part 1 in our Research and Development facility. Years of experience and close association with various authorities in the fields of fluid flow, thermodynamics, noise control and machine design has contributed significantly to the pool of intellectual property held by the company. Custom fans for unique applications are designed and developed using structured and fluid dynamics and proprietary design software.

CFW Fans Vision

CFW aims to be recognized as the best provider of overall value and service in the design & manufacture of quality industrial fans to all market sectors.

CFW is committed to providing quality products and excellent service to satisfy customers’ requirements, timeously, at competitive prices, through continued market research and product development, thus maintaining sustainability in the global arena.

To accomplish this, we seek to develop staff, the group’s most valued asset, through training and by creating an environment in which every person can reach their true potential.

The means through which we provide value to our clients include:

- Professional design expertise.

- Maintaining a multi-disciplined resource base.

- Developing our own technology and maintaining our own manufacturing and design facilities, which enables us to offer superior backup and support to our customers.

- Creating optimum solutions to suit the customer’s application.

- Designing and manufacturing products according to international best practice.

- Providing a quality product guarantee.

- Offering a range of support services such as fan systems energy optimization and OEM after-sales support.

- Maintaining an SABS ISO 9001 certified quality management system.

Associations

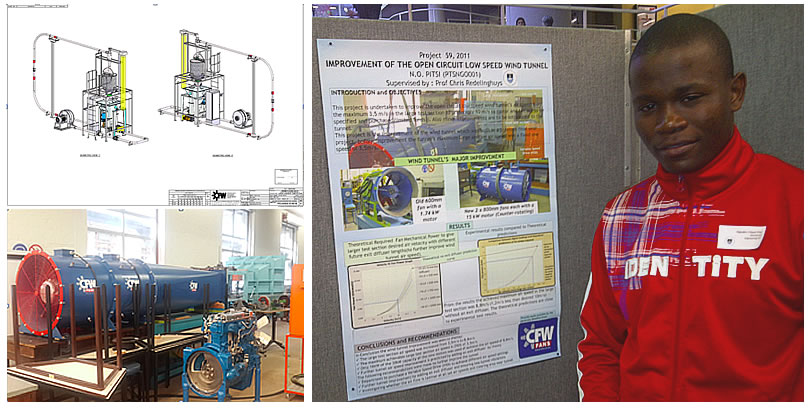

CFW Fans values its close association with the University of Cape Town (UCT) since 1970, where from humble beginnings, its first range of centrifugal fans was tested.

CFW has participated in various projects over the years where expertise has been shared to improve technology in industry and at the same time provided skills training for graduates. Graduates have spent time at CFW gaining practical experience, and some have completed the experimental component of their thesis with the support of CFW.

Above is a multi-stage contra-rotating axial flow fan unit which was donated to UCT Mechanical Engineering Department Fluids Laboratory to improve their wind tunnel capability and to assist their students’ experimental project work.

CSIR – National Cleaner Production Centre (NCPC)

Fan System Optimisation Training

CFW Fans has been privileged to participate in the Industrial Energy Efficiency (IEE) Improvement project in South Africa. Initial expertise and training was provided by the United Nations Industrial Development Organisation (UNIDO) using international trainers to promote awareness & knowledge around energy efficiency, and grow local capacity and trainers. Many of CFW staff members have benefited from participating in the IEE training courses jointly implemented by UNIDO and the National Cleaner Production Centre South Africa (NCPC-SA) hosted by the CSIR. CFW has been committed to the initiative and one of its senior technical representatives serves the program as the lead Fan System Optimisation Expert Level Trainer in South Africa, and as a co-trainer internationally in Fan System Optimisation.

CFW’s passion is made evident by substantial investment in R & D, using its test laboratory to continuously improve fan efficiencies. Fan retrofit technology provides customers with an opportunity to improve the energy efficiency of their plants and meet their emission targets. Payback periods on these initiatives are often less than 24 months.

CFW is authorised to provide private Fan System Optimisation courses to industry and its customer using the UNIDO course material.

CFW Clients

CFW prides itself on forging lasting customer relationships. Combining decades of fan engineering expertise, extensive fan applications knowledge and a passion for excellence, CFW is in a position to satisfy each clients unique needs and provide superior after-sales service.

- ArcelorMittal

- City of Cape Town

- Consol Glass

- De Beers

- Enviroserve Eskom

- Exxaro

- Fine Chemicals

- Irvin & Johnson

- John Thompson

- Boilers

- Johnson Matthey

- Kaap Agri

- Mercedes Benz

- Nampack

- Oceana Fishing

- PetroSA

- PG Bison

- PPC Cement

- Premier Foods

- SAB Miller

- Safal Steel

- Sea Harvest

- Tiger Brands

- Tongaat Hulett

- Starch

- Toyota

- Volkswagen

CFW FANS ACCREDITATION

ISO 9001:2008 QMS Accredited (certificate)

Merseta Top Training Company (certificate)

Construction Industry Develpopment Board (CIDB) Vendor (certificate)

Broad Based Economic Empowerment (BBBEE) Level 4